What Factors Should I Consider When Purchasing Cpa Email Lists? When purchasing an CPA (Certified Public Accountant) email list, it's important to examine a variety of key aspects to ensure that the list you purchase is high-quality, compliant with legal standards and pertinent to your marketing goals. Here's what to look for:1. Data Quality and Ac

30 Great Tips For Choosing Oxplay Sites

Top 10 Tips To Help You Choose The Best Game For Your Online Betting Platform In Indonesia The variety of games available can be a major aspect in improving your betting experience online. Diverse games give you greater betting options and can provide an enjoyable and diverse experience. Here are the 10 best ways to evaluate the game options availa

30 New Reasons For Picking 7 Raja Togel Sites

Top 10 Tips For 7raja Togel Indonesian Online Betting Platforms In Relation To Payment Options Payment options play a major aspect in evaluating 7 Raja Togel Indonesian-based betting platforms. Options for payment can affect the overall experience of gambling. Here are the top 10 guidelines on assessing payment options for 7 Raja Togel Indonesian b

30 Pro Reasons For Picking ASIAN2BET Login Sites

Paying For Online Gambling In Indonesia: 10 Tips Payment options are an important aspect to take into account when looking at IDNPLAY Indonesian betting sites. The availability, security and ease of payment methods can greatly affect your overall betting experience. Here are the top 10 tips to evaluate ASIAN2BET Login Indonesian online betting plat

30 Excellent Reasons For Picking TAJIR4D Sites

The 10 Best Tips For Payment Alternatives For tajir4d togel Indonesian Online Betting Platforms Payment options are an important factor to consider when evaluating tajir4d Indonesian betting platforms. Payment options can affect the overall experience of gambling. These are the top 10 ways to assess the payment options available on tajir4d Indonesi

Tony Danza Then & Now!

Tony Danza Then & Now! Sam Woods Then & Now!

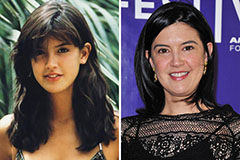

Sam Woods Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!